Zhejiang Yanpeng Nonwoven Machinery Co.,Ltd.---A professional non woven production line Manufacturer

11. 2020

Quick service response time

Provide 7x24 hours of uninterrupted

service for you

Professional one to one customer service

Escort your production

Address: Wanchuan Road, Binhai New District, Pingyang County ,Zhejiang, China

Tel: 0086-577-58198758

Fax: 0086-577-58198759

Fill in your project information

As we all know, medical masks must have three layers, with spunbonded nonwovens on both sides and melt blown nonwovens with enough weight in the middle.

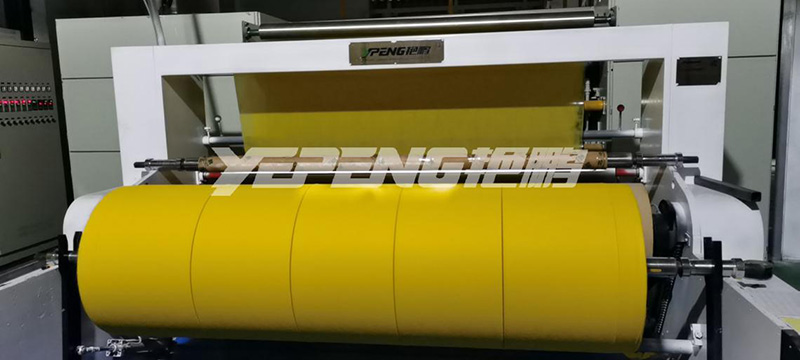

The figure shows the meltblown cloth. The filtration effect depends on the weight of the cloth in grams per square meter. This range is 18-500g, 40-50g above the filtering effect is good.

It's easy to identify the inferior products of two layers, but it's hard to say the three layers. In short, a good melt blown fabric is white rather than transparent because of the weight of gram, and it is obviously different from the spunbonded nonwovens on both sides (frankly speaking, it looks like paper, but the fire can't ignite, it turns black and drops down, but there is no flame burning). If the middle layer looks the same as the two sides, it is not meltblown cloth. If it looks different but obviously thin, it is a small gram of meltblown cloth. The thinner the melt blown cloth, the worse the effect. This is the difference between medical (Nursing) masks and medical surgical masks. And the same medical (Nursing) mask, also different thickness.

1. Spunbonded nonwoven fabric is not easy to tear and will not touch hands due to static electricity. The qualified melt blown nonwoven fabric is easy to tear, and it will be contaminated by static electricity.

2. Spunbonded nonwoven fabric and melt blown non-woven fabric are both polypropylene products with little difference in combustion.

3. The fusible blown fabric which is close to white and similar paper towel materials should be distinguished by burning, and the spunbonded non-woven fabric and the qualified melt blown non-woven fabric should be distinguished with or without electrostatic effect.

Spunbonded nonwovens

Spunbonded nonwovens

After the polymer has been extruded and stretched to form continuous filament, the filament is laid into a net, and the fiber mesh is then self bonded, thermally bonded, chemically bonded or mechanically reinforced to turn the web into a non-woven fabric.

characteristic:

1. The fiber mesh is composed of continuous filament.

2. Excellent tensile strength.

3. There are many changes in the process, and various methods can be used to reinforce.

4. Wide range of filament size variation.

Product application:

1. Polypropylene (PP): geotextile, tufted carpet base cloth, coating base cloth, medical and health materials, coating materials of disposable products, etc.

2. Polyester (PET): filter material, lining material, tufted carpet base cloth, agricultural material, packaging material, etc.

Melt blown nonwoven fabric

Melt blown nonwoven fabric

Melt blown non-woven fabric process: polymer feeding - melt extrusion - fiber formation - fiber cooling - Netting - reinforcement into cloth.

characteristic:

1. The web consists of very fine, short fibers.

2. Good uniformity and soft handle.

3. Good filtration and absorption performance.

4. The net strength is poor.

Product application: filter materials, medical and health materials, clothing materials, battery diaphragm materials, wiping materials.

11. 2020

11. 2020

11. 2020

10. 2020